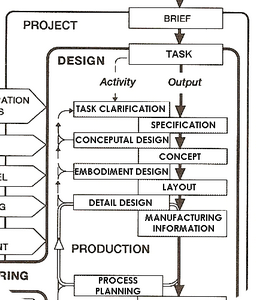

Product Development Process

Product Specification

The first phase in new product development process is a comprehensive orientation session that will allow EME to create the Product Specification Document. This document is a useful tool for defining and specifying project goals and objectives, prior to entering the conceptual development phase.

Conceptual Development

We then generate conceptual drawings using the Product Specification Document as a guideline, to explore different aesthetics, ergonomics and manufacturability approaches on a given project. The client is presented with multiple conceptual designs in a photo-realistic rendering format and an exploded view illustrating part breakups and preliminary manufacturing costs.

Engineering & Cad Development

Using the latest in Computer Aided Engineering (CAE) software, complete with surface and solid-modeling capabilities, enables us to assist clients in expediting product delivery to the market. EME's 3D solid modeling capability will further accelerate the product development process as it can be used to simulate real world environments by conducting dynamic motion mechanisms as well as stress and strain analysis of parts and assemblies to validate the design integrity.

Engineering Documentation

EME's engineering department will refine the 3D CAD data into comprehensive production documentation. This will include the creation of 2D drawings with ANSI standard production documentation to serve as a reference for quality control as well as generating a Bill of Materials (BoM) for the entire assembly.

Prototyping

EME will work with our prototyping partners (or use our in-house 3D printer) to create rapid prototypes of the chosen designs, which will represent actual size and proportions of the proposed design approaches. These rapid prototypes will serve to further assist in the form study discussions and decision-making.

Functional Model

Working with our manufacturing partners, EME will have a working pre-production model for testing and evaluation. This model will be an accurate representation of the finished product, as well as the final checkpoint for the finalized engineering assembly.

Vendor Liaison

EME offers assistance to our clients in the final process of bringing the engineered product to production by serving as a vendor liaison. We can interface with potential vendors and oversee the transition to the initial production of parts and assemblies.

Find out today how we can help make your project a sucess!

Call us at (813) 966-3667

Elting Mechanical Enterprises - 3413 S. Lightner Dr., Tampa, FL 33629

Copyright © 2006 - 2019 Elting Mechanical Enterprises, Inc.